Trunnion Mounted Ball Valve, Metal Seat Type

Design acc.to API 6D, DIN3357

Face-to-Face acc. to ASME B16.10

Flange acc. to ASME B16.5, DIN EN1092

Butt Weld acc. to ASME B16.25

Test acc. to API 598, DIN3230

Fire Proof acc. to API607

Anti-H2S acc. to NACE MR-0175

Size from 2” to 20”

Pressure from 150LB to 1500LB, PN16 to PN250

Material:ASTM including A216 WCB, A352 LCB, A352 LCC,A351 CF8,A351 CF8M, A351 CF3,A351 CF3M, A217 WC6, A217 WC9, A217 C5, A217 C12, A217 C12A, A890 4A, A890 5A, A105(1.0460), A350 LF1, A350 LF2,A350 LF3,A182 F304,A182 F316, A182 F304L, A182 F316L, A182 F11,A182 F22, A182 F5, A182 F9, A182 F91, A182 F51, A182 F53, A182 F55,etc.

DIN including GS-C25, 1.0619,1.0460(C22.8), 1.4308, 1.4408, etc.

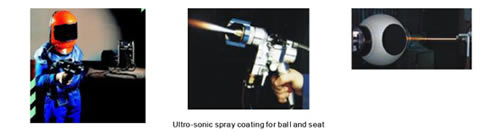

Sealing Material:nickel based alloy,tungsten carbide,chrome carbide,etc.

Features:

1.Blow-out proof stem

For the purpose of preventing the stem from flying off resulting in abnormal rising of the inner pressure of valve,shoulder is fixed at the lower part of the stem.In addition,in order to prevent leakage resulting from burnout of packing set of the stem in a fire,thrust bearing is set at the contact position of the shoulder at lower part of the stem and valve body.Thus an inverse seal seat is formed which will prevent leakage and avoid accident.

2.Key lock

Locks can be used to lock the manual valve when it is fully open or closed so as to prevent non-working personnel from pulling the handle which may result in misoperation of valve.It can also avoid opening or closing of valve resulting from the shock from pipelines or unpredictable factors that may cause an accident.For working pipelines such as combustible and explosive oil,gas and chemical medium,or for field piping site,the locking mechanism is especially useful.

3.Free leakage of body Sealed construction

The connective position of valve body and bonnet is double sealed by gasket and O-ring,on this base,such factors as fire,high temperature,shock and uneven opening or closing of the torque all can not induce external leakage.

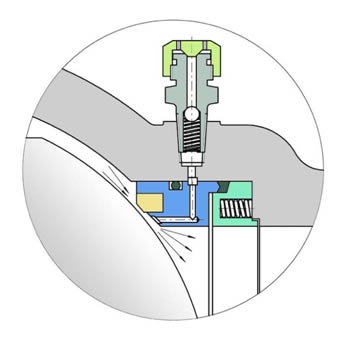

4. Double block&bleed(DBB)

When ball is full open or close position,the transmitter substance in center cavity of body can be released by drainage and emptying devices.In addition,the over loaded pressure in the center cavity of valve can be released to low pressure end by self relief seat.

5.Emergency sealing

Compound injection holes are designed and compound injection valves are installed at locations of stem/cap and body support of side valve.When sealing of stem or seat is damaged to induce leakage,the compound can be used to do the second time sealing.A concealed check valve is installed in side of each compound injection valve to prevent compound from out flowing due to the action of transmitter substance.The top of the compound injection valve is the connector for fast connection with compound injection gun.

6.Automatic body cavity relief

When the body pressure going up un-normally as the unstable factor,the trunnion ball valve downstream seat will be pushed by unnormal pressure,and the release the un-normally pressure automatically,it doesn't damage to the sealing of upstream seat.